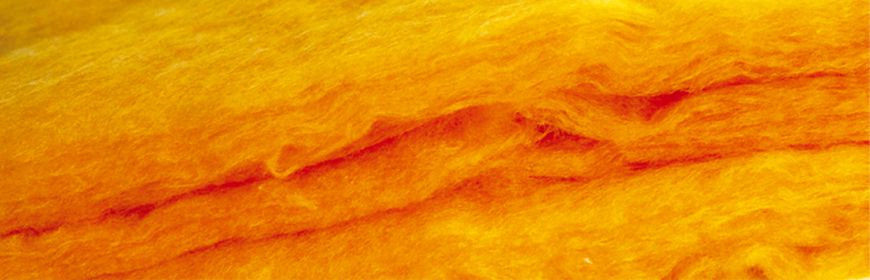

Wadding/Interlining/Batting

Textile fillers:

ompared with the traditional warm material, in the same conditions, can be lighter and thinner;even in the wet environment can still be effectively warm.

Meanwhile, the material is flame retardant, non-toxic, far infrared,with good heat storage abilities.

Fiber content and width can be customized:

| No | Component ratio | Characteristic |

| 1 | 100% Veenice fiber

|

far infrared,flame retardant ,Warmth retention Skin adaptability ,Antibacterial |

| 2 | 50% veenice fiber, 50% Polyester

|

far infrared,flame retardant ,Warmth retention Skin adaptability ,Antibacterial |

| 3 | 15% veenice fiber, 85% Polyester |

far infrared,Warmth retention Skin adaptability ,Antibacterial |

Here under are the Polyimide Fiber warm test data compare with Cashmere and polyester:

| Test data | unit | Polyimide | Cashmere flakes | polyester |

| Fineness | dtex | 2.2,1.67,0.89 | — | 2.2 |

| Lengter | mm | 38,51 | 38 | 51 |

| CLO value | 123g/㎡ | 1.41 | 1.39 | 1.07 |

| thermal resistance | ㎡·K/W | 0.219 | 0.216 | 0.166 |

| heat transfer coefficient | W/㎡·K | 4.58 | 4.66 | 6.03 |

| Weight | g/㎡ | 119g/m² | 123g/m² | 123g/m² |

| reduced heat preservation rate | % | 76.5% | 70.1% | 64.9% |